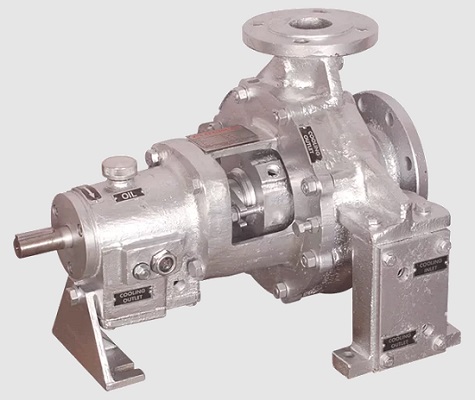

Centrifugal pumps are among the most popular and frequently

used pumps worldwide. Depending upon the application, the ideal centrifugal

pump has to be selected. If you're in the marketplace searching for centrifugal

pumps, you would certainly have come across the term "multistage

centrifugal pumps". Wondering if it's the appropriate selection

for your demands? Allow us to aid.

Single-stage

Centrifugal Pump vs Multistage Centrifugal Pump: What's the Difference?

As the names imply, the vital difference between the two is

the variety of impellers (also referred to as stages). Single-stage centrifugal

pumps have only one impeller. On the other hand, multistage pumps have two or

even more impellers.

The impeller plays an essential function in the procedure of

a centrifugal pump. It pressurizes

and moves the fluid/liquid. Since multistage pumps have more than one impeller,

the circulation rate and stress varieties in a multistage are much more

reliable than single-stage pumps.

Therefore, it functions like a chain of single-stage pumps

linked linearly. As the liquid moves from one phase to the following, the

stress climbs while the flow continues to be consistent.

As a result, multistage centrifugal pumps generate higher

power and greater stress with small electric motors, consequently utilizing

less power.

Where are multistage

centrifugal pumps used?

Multistage centrifugal pumps are used in numerous industrial

applications as a result of their ability to transfer fluids at greater

pressures. Here are various industries that use multistage centrifugal pumps:

- Fire fighting - Generates high-pressure water made use of in

snuffing out fires.

- Boiler feedwater - To pump feedwater into a heavy steam

boiler.

- High-pressure cleansing - Generates a high-pressure stream

of water to tidy dirt and dust off items like cars, home windows, and so on

- Irrigation - Multistage pumps are utilized to pump water by

means of a watering system.

- Water circulation - Multistage pumps add stress to the

system, helping in the continuous blood circulation of water.

- Snowmaking - Used in pressurizing water for man-made snow

generation.

Different Types of Multistage Centrifugal Pumps

Multistage centrifugal pumps can be categorized into 2

kinds:

- Horizontal centrifugal pumps

- Vertical centrifugal pumps

What are horizontal multistage centrifugal

pumps?

Horizontal multistage pumps are one of the most frequently

made use of pumps and are used in numerous of the applications mentioned above.

In this pump, the fluid travels horizontally with several impellers. Horizontal

pumps can handle greater circulation prices than vertical pumps (the one

exception to this rule is vertical wind turbine pumps that can deal with

greater circulation prices). It's easy to recognize horizontal multistage pumps

by means of their fractional covering.

Regardless of all the benefits, horizontal multistage pumps have certain drawbacks. They are:

- Maintenance intensive

- Need proficient pump operators

- It can be a lot more costly compared to vertical multistage

pumps

What are vertical

multistage centrifugal pumps?

Vertical pumps are not extensively made use of like

horizontal pumps. Their applications are restricted. As the name indicates,

these pumps are up and down oriented, with the impellers are put on top of each

other. The clearances in vertical

centrifugal pumps are smaller than their straight counterparts. This makes

them optimal for clean-water applications.

These pumps are perfect for applications that do not have

ample floor room. They can supply higher pressures with just one motor and a

single pump body. Vertical multistage pumps have certain constraints like:

- They cannot take care of solids or debris

- More likely to deadhead

Deadheading is when the water inside the pump spins

continually, thereby transforming the water right into vapour. Deadheading

reasons permanent damages to centrifugal pumps.

SMS Pumps & Engineers: The No. 1 Manufacturer of Centrifugal Multistage Pumps in India

SMS Pumps & Engineers is a world-known centrifugal

chemical pump manufacturer and supplier in Ahmedabad, India. We provide

a wide range of commercial pumps for various markets like food processing,

chemical plants, paper manufacturing, seawater desalination plants, sugar

handling, and many more. We additionally use skilled preventative upkeep advice

post-sales. Connect with our team to discover the best thermic

fluid pumps matched to your needs.

SURVEY

How Did You Hear About Us?

SURVEY

How Did You Hear About Us?

Comments